Tel : 0086 21 3783 1829

E-mail : info@denair.net

Tel : 0086 21 3783 1829

E-mail : info@denair.net

For screw air compressor, it is very important to make a good maintenance to get a long life, so you will wonder how to maintain the machine, now let us make screw air compressor maintenance guide.

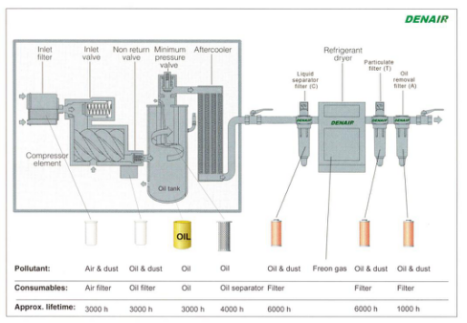

The main maintenance parts for screw air compressor is air filter, oil filter, oil separator and oil.

the air filter can protect the machine from air dust pollution, in order to protect the air end with a long life, the oil filter is filtering the dust which is not be filtered from the air filter, the oil is a consumable part, the machine working should use lot of oil to lubricate the air end, cool the compressed air, reduce the noisy and make a full sealed space to avoid leaking, when the machine is not enough oil, you should add it, the oil separator is for separating the oil from the compressed air, which can ensure the compressed air with less oil.

The maintenance time for air filter is about 3000H, oil filter is about 3000H, oil is 3000-4000H, and oil separator is about 4000H, but this is not absolute, it depends on the user condition, it the user condition is bad, the time should be cut short.

Related Information:

Privacy Policy © 2006 Denair Energy Saving Technology (Shanghai) PLC.