Tel : 0086 21 3783 1829

E-mail : info@denair.net

Tel : 0086 21 3783 1829

E-mail : info@denair.net

Working Pressure :

7-10[ bar ]Free Air Delivery :

206-1994[ cfm ]Working Power :

55-250[ kw ]

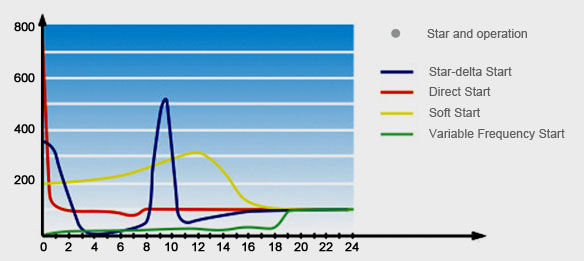

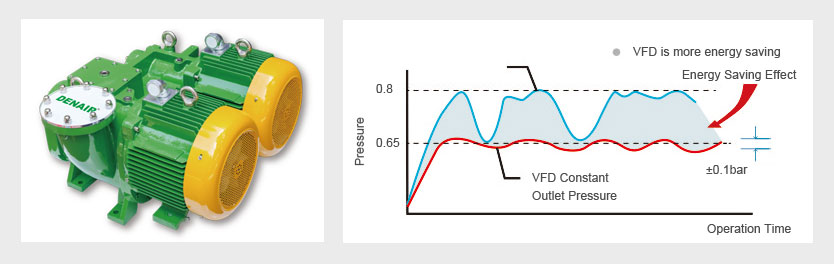

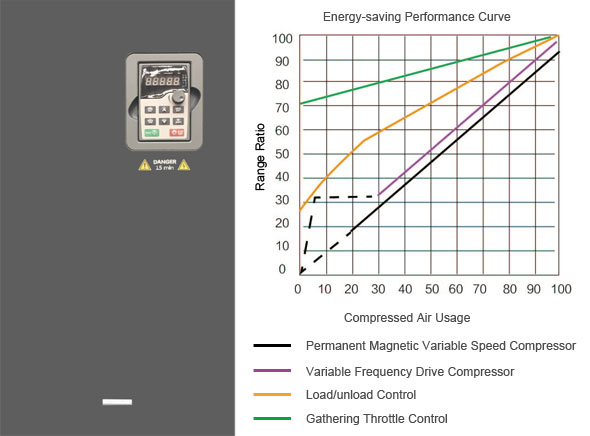

01 Features Of permanent Magnet Variable Frequency Air Compressor

02 Air End

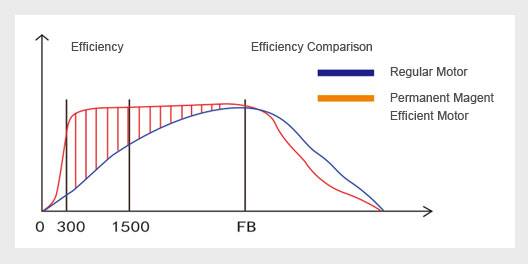

03 Advantages of Permanent Magnet Motors Compared to General Asynchronous Motors

04 Stainless Steel Piping Design

05 More Advanced Technology. More Powerful Inverter

06 Oil Filter

07 Air Filter

| Model | Maximum working pressure | Capacity(FAD) |

Installed motor power |

IP Grade | Noise level | Dimensions(mm) | Weight |

Air outlet pipe diameter |

Starting Method |

EEI | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| bar(g) | psig | m3/min | cfm | kw | hp | (L) | (W) | (H) | kg | ||||||

| DAV-55+ | 7 | 102 | 6.46-12.93 | 228-457 | 55 | 75 | IP54 | 75 | 1900 | 1500 | 1590 | 1500 | DN50 |

Direct Driven |

EEI1 |

| 8 | 116 | 6.32-12.63 | 223-446 | ||||||||||||

| 10 | 145 | 5.83-11.66 | 206-412 | ||||||||||||

| DAV-75+ | 7 | 102 | 7.99-15.98 | 282-564 | 75 | 100 | IP54 | 75 | 1900 | 1500 | 1590 | 1700 | DN50 | ||

| 8 | 116 | 7.89-15.79 | 279-558 | ||||||||||||

| 10 | 145 | 7.12-14.24 | 251-503 | ||||||||||||

| DAV-90+ | 7 | 102 | 10.81-21.62 | 382-763 | 90 | 120 | IP54 | 78 | 2650 | 1700 | 1850 | 2550 | DN80 | ||

| 8 | 116 | 10.18-20.36 | 359-719 | ||||||||||||

| 9 | 131 | 9.92-19.83 | 350-700 | ||||||||||||

| 10 | 145 | 9.41-18.81 | 332-664 | ||||||||||||

| DAV-110+ | 7 | 102 | 12.52-25.04 | 442-884 | 110 | 150 | IP54 | 78 | 2650 | 1700 | 1850 | 2550 | DN80 | ||

| 8 | 116 | 12.07-24.14 | 426-852 | ||||||||||||

| 9 | 131 | 11.46-22.93 | 405-810 | ||||||||||||

| 10 | 145 | 11.09-22.19 | 392-784 | ||||||||||||

| DAV-132+ | 7 | 102 | 15.15-30.29 | 535-1070 | 132 | 175 | IP54 | 78 | 2650 | 1700 | 1850 | 3100 | DN80 | ||

| 8 | 116 | 14.53-29.06 | 513-1026 | ||||||||||||

| 9 | 131 | 13.49-26.99 | 476-953 | ||||||||||||

| 10 | 145 | 12.09-24.18 | 427-854 | ||||||||||||

| DAV-160+ | 7 | 102 | 18.45-36.91 | 651-1303 | 160 | 215 | IP54 | 80 | 3000 | 1950 | 2030 | 4000 | DN100 | ||

| 8 | 116 | 17.63-35.26 | 623-1245 | ||||||||||||

| 9 | 131 | 16.47-32.94 | 581-1163 | ||||||||||||

| 10 | 145 | 15.72-31.44 | 555-1110 | ||||||||||||

| DAV-185+ | 7 | 102 | 21.05-42.11 | 743-1487 | 185 | 250 | IP54 | 80 | 3000 | 1950 | 2030 | 4300 | DN100 | ||

| 8 | 116 | 19.79-39.58 | 699-1398 | ||||||||||||

| 9 | 131 | 18.74-37.47 | 662-1323 | ||||||||||||

| 10 | 145 | 17.89-35.79 | 632-1264 | ||||||||||||

| DAV-200+ | 7 | 102 | 22.25-44.49 | 786-1571 | 200 | 270 | IP54 | 85 | 3000 | 1950 | 2030 | 4700 | DN100 | ||

| 8 | 116 | 21.31-42.61 | 752-1505 | ||||||||||||

| 9 | 131 | 19.30-38.60 | 681-1363 | ||||||||||||

| 10 | 145 | 17.85-35.71 | 630-1261 | ||||||||||||

| DAV-220+ | 7 | 102 | 24.14-48.28 | 852-1705 | 220 | 300 | IP54 | 85 | 3500 | 2200 | 2300 | 5000 | DN125 | ||

| 8 | 116 | 23.91-47.82 | 844-1689 | ||||||||||||

| 9 | 131 | 22.89-45.79 | 808-1617 | ||||||||||||

| 10 | 145 | 20.42-40.83 | 721-1442 | ||||||||||||

| DAV-250+ | 7 | 102 | 28.24-56.48 | 997-1994 | 250 | 350 | IP54 | 85 | 3500 | 2200 | 2300 | 5500 | DN125 | ||

| 8 | 116 | 26.54-53.08 | 937-1874 | ||||||||||||

| 9 | 131 | 25.45-50.89 | 899-1979 | ||||||||||||

| 10 | 145 | 23.00-46.00 | 812-1624 | ||||||||||||

*) FAD in accordance with ISO 1217:2009, Annex C: Ansolute intake pressure 1 bar (a), cooling and air intake temperature 20℃

**) Nosie level as per ISO 2151 and the basic standard ISO 9614-2, operation at maximum operating pressure and maximum speed; tolerance:±3 dB(A)

Specifications are subject to change without prior notice

| Model | Maximum working pressure | Capacity(FAD) |

Installed motor power |

IP Grade | Noise level | Dimensions(mm) | Weight |

Air outlet pipe diameter |

Starting Method |

EEI | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| bar(g) | psig | m3/min | cfm | kw | hp | (L) | (W) | (H) | kg | ||||||

| DAV-55+ | 7 | 102 | 6.46-12.93 | 228-457 | 55 | 75 | IP54 | 75 | 1900 | 1500 | 1590 | 1500 | DN50 |

Direct Driven |

EEI1 |

| 8 | 116 | 6.32-12.63 | 223-446 | ||||||||||||

| 10 | 145 | 5.83-11.66 | 206-412 | ||||||||||||

| DAV-75+ | 7 | 102 | 7.99-15.98 | 282-564 | 75 | 100 | IP54 | 75 | 1900 | 1500 | 1590 | 1700 | DN50 | ||

| 8 | 116 | 7.89-15.79 | 279-558 | ||||||||||||

| 10 | 145 | 7.12-14.24 | 251-503 | ||||||||||||

| DAV-90+ | 7 | 102 | 10.81-21.62 | 382-763 | 90 | 120 | IP54 | 78 | 2650 | 1700 | 1850 | 2550 | DN80 | ||

| 8 | 116 | 10.18-20.36 | 359-719 | ||||||||||||

| 9 | 131 | 9.92-19.83 | 350-700 | ||||||||||||

| 10 | 145 | 9.41-18.81 | 332-664 | ||||||||||||

| DAV-110+ | 7 | 102 | 12.52-25.04 | 442-884 | 110 | 150 | IP54 | 78 | 2650 | 1700 | 1850 | 2550 | DN80 | ||

| 8 | 116 | 12.07-24.14 | 426-852 | ||||||||||||

| 9 | 131 | 11.46-22.93 | 405-810 | ||||||||||||

| 10 | 145 | 11.09-22.19 | 392-784 | ||||||||||||

| DAV-132+ | 7 | 102 | 15.15-30.29 | 535-1070 | 132 | 175 | IP54 | 78 | 2650 | 1700 | 1850 | 3100 | DN80 | ||

| 8 | 116 | 14.53-29.06 | 513-1026 | ||||||||||||

| 9 | 131 | 13.49-26.99 | 476-953 | ||||||||||||

| 10 | 145 | 12.09-24.18 | 427-854 | ||||||||||||

| DAV-160+ | 7 | 102 | 18.45-36.91 | 651-1303 | 160 | 215 | IP54 | 80 | 3000 | 1950 | 2030 | 4000 | DN100 | ||

| 8 | 116 | 17.63-35.26 | 623-1245 | ||||||||||||

| 9 | 131 | 16.47-32.94 | 581-1163 | ||||||||||||

| 10 | 145 | 15.72-31.44 | 555-1110 | ||||||||||||

| DAV-185+ | 7 | 102 | 21.05-42.11 | 743-1487 | 185 | 250 | IP54 | 80 | 3000 | 1950 | 2030 | 4300 | DN100 | ||

| 8 | 116 | 19.79-39.58 | 699-1398 | ||||||||||||

| 9 | 131 | 18.74-37.47 | 662-1323 | ||||||||||||

| 10 | 145 | 17.89-35.79 | 632-1264 | ||||||||||||

| DAV-200+ | 7 | 102 | 22.25-44.49 | 786-1571 | 200 | 270 | IP54 | 85 | 3000 | 1950 | 2030 | 4700 | DN100 | ||

| 8 | 116 | 21.31-42.61 | 752-1505 | ||||||||||||

| 9 | 131 | 19.30-38.60 | 681-1363 | ||||||||||||

| 10 | 145 | 17.85-35.71 | 630-1261 | ||||||||||||

| DAV-220+ | 7 | 102 | 24.14-48.28 | 852-1705 | 220 | 300 | IP54 | 85 | 3500 | 2200 | 2300 | 5000 | DN125 | ||

| 8 | 116 | 23.91-47.82 | 844-1689 | ||||||||||||

| 9 | 131 | 22.89-45.79 | 808-1617 | ||||||||||||

| 10 | 145 | 20.42-40.83 | 721-1442 | ||||||||||||

| DAV-250+ | 7 | 102 | 28.24-56.48 | 997-1994 | 250 | 350 | IP54 | 85 | 3500 | 2200 | 2300 | 5500 | DN125 | ||

| 8 | 116 | 26.54-53.08 | 937-1874 | ||||||||||||

| 9 | 131 | 25.45-50.89 | 899-1979 | ||||||||||||

| 10 | 145 | 23.00-46.00 | 812-1624 | ||||||||||||

*) FAD in accordance with ISO 1217:2009, Annex C: Ansolute intake pressure 1 bar (a), cooling and air intake temperature 20℃

**) Nosie level as per ISO 2151 and the basic standard ISO 9614-2, operation at maximum operating pressure and maximum speed; tolerance:±3 dB(A)

Specifications are subject to change without prior notice

You may Like:

If you are interested in DENAIR air compressor, please contact us via

email: info@denair.net or send your inquiry in the form below.we will reply you within 24 hours.

*

*

*

© 2006 Denair Energy Saving Technology (Shanghai) PLC.