Tel : 0086 21 3783 1829

E-mail : info@denair.net

Tel : 0086 21 3783 1829

E-mail : info@denair.net

Pumping Speed :

180-720[ m3/h ]Extreme Pressure :

0.02[ mbar ]Motor Power :

5.5-22[ kW ]

Exhaust Path Is Short, Reduce The Deposition Of Reactants.

The Optimal Linear Sealing, The Pump Performance

Simple Structure, Low Fault Rate And Easy Maintenance

Microcomputer Operation, Remote Monitoring, Considerate Protection

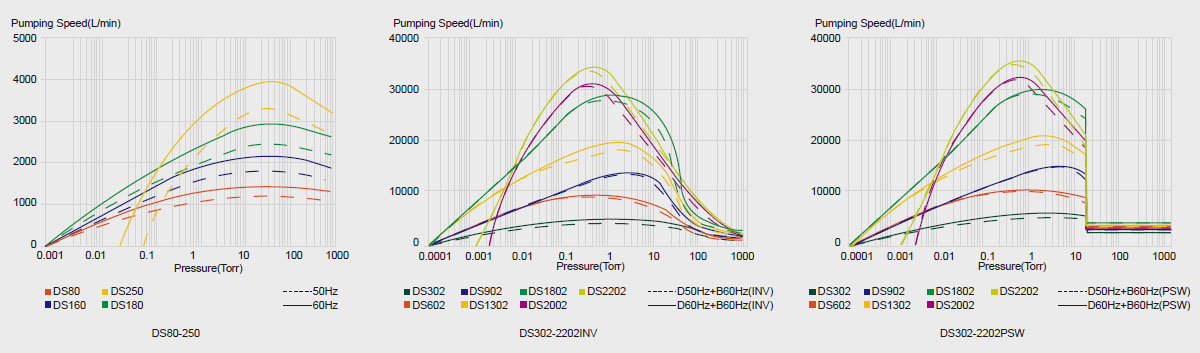

| Model | Unit | DS180 | DS250 | DS360 | DS540 | DS720 | |

|---|---|---|---|---|---|---|---|

| Pumping Speed (50/60Hz) | m3/h | 180/216 | 250/300 | 396/475 | 540/650 | 720/850 | |

| L/min | 3000/3600 | 4200/5000 | 6600/7920 | 9000/10800 | 12000/14400 | ||

| L/S | 50/60 | 70/84 | 110/132 | 150/180 | 200/240 | ||

| Extreme Pressure (50/60Hz) | mbar | 0.02/0.01 | |||||

| Torr | 0.015/0.0075 | ||||||

| Pa | 2/1 | ||||||

| Power (kW) 50/60Hz | 5.5/7.5 | 7.5/7.5 | 11/15 | 15/15 | 22/22 | ||

| Speed (RPM) 50/60Hz | 2900/3500 | ||||||

| Inlet Diameter (mm) | 50 | 65 | 70 | 90 | 100 | ||

| Outlet Diameter (mm) | 40 | 40 | 55 | 65 | 65 | ||

| Gear Chamber Oil Capacity (L) | 0.85 | 0.85 | 1.4 | 2 | 2 | ||

| Cooling Water | L/min | 2.5 | 2.6 | 2.8 | 3 | 4 | |

| gal/min | 0.67 | 0.7 | 0.75 | 0.8 | 1.07 | ||

| Weight (Kg) | 295 | 350 | 480 | 520 | 680 | ||

| Noise (dB(A)) | 75 | 78 | 82 | 85 | 86 | ||

| Operation Temp (℃) | 5-40 | ||||||

| Operation Moisture | 90% | ||||||

You may Like:

If you are interested in DENAIR air compressor, please contact us via

email: info@denair.net or send your inquiry in the form below.we will reply you in 24 hours.

*

*

*

© 2006 Shanghai Denair Compressor Co.,Ltd.