Oil-free Diesel Driven Air Compressor

L Series

Working Pressure: 10bar; 145psig

Free Air Delivery: 26, 45m3/min; 900, 1600cfm

Rated Power: 265, 410kW; 360, 550hp

OIL FREE – WHERE YOU NEED IT TO BE

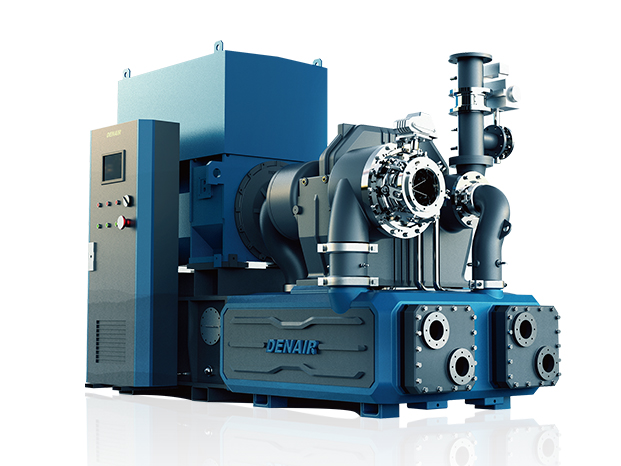

More air compressor applications than ever require oil free air. Sensitive plant operations require a reliable source of oil free backup air. DENAIR compressors, based on diesel engines, have updated the main system to achieve a combination of diesel mobile units and oil-free compressor performance.

Oil free air in a portable package

DENAIR air compressor is built for long-lasting performance and brings class 0 oil free air directly where it is needed — Oilfield, refinery, outdoor factory.

The portable air compressors provide class 0 oil-free air in a package designed for both short-term and long-term use. GHH oil-free two-stage air end provides you with sufficient oil-free air and is equipped with a powerful CUMMINS diesel engine drive.

Advantages & Benefits of Oil-free Diesel Driven Air Compressor:

♦ Highest Air Quality

100% oil-free clean air, providing safety for the food, petroleum and chemical industries.

♦ Easy to Move

Running Gear with Steerable Front Axle, for quick and easy transport onsite.

♦ Reduce Your Operating Cost

Emission DENAIR oil-free air technology helps you to avoid expensive filter replacements, cuts the cost of oil condensate treatment and reduces energy loss from pressure drops in filters.

♦ Easy to Operate

Touch screen controller for easy access to all compressor operation data and pressure adjustment.

♦ Efficient Cooling System

Large enough margin to ensure stable use in high-temperature environments for long periods of time.

5 coolers: compressor inter cooler + compressor oil cooling + engine inter cooling + engine water cooling + compressor after cooling.

♦ Minimal Downtime

Large fuel tank design, can be connected to external fuel tank, can be long time continuous operation.

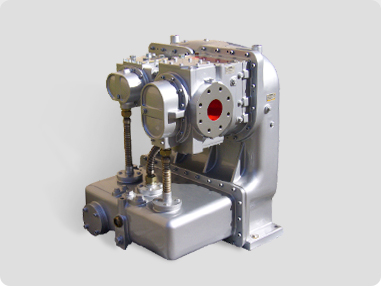

State-of-the-art Screw Element: - Original Germany GHH air end

- Double stage compression

- Superior Sweden SKF element bearings

- A high-power engine model is selected, with adjustable displacement ranging from 65% to 100%, providing substantial torque at low speeds for easy starting.

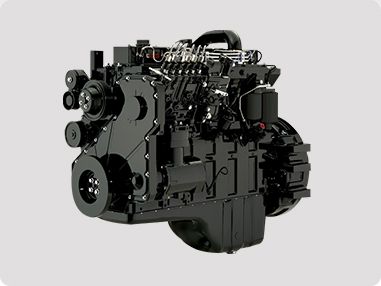

Diesel Engine:Heavy Duty and Less Fuel Consumption Compared to Similar engine Designs, better in durability and longevity.

Intelligent Controller:- IP65 rated for complete dust and waterproof protection

- LCD color screen

- User-friendly pressure setting interface

- Easy diagnosis and operation

Superior Air Filter and Oil Filter:- Superior air filter with two-stage dust removal and filtering system with effciency of up to 99.9% even in heavy-duty environments

- Extends the service life of the compressor parts and components, ensures high air quality

- Quality oil filter with excellent oil purification capability ensures a clean and safe oil system

- Long service period and easy filter change reduce maintenance costs.

Cooler System:- Adopting large cooling area design, oil-cooled and water-cooled side-by-side dual cooling method, independent fins and channels, uniform cooling, good heat dissipation, high temperature resistance, suitable for use in harsh environments such as high temperature and high humidity in the field;

- Low-speed and large-angle axial fan ensures sufficient cooling airflow while controlling the operation noise to a lower level;

- Fan, belt and other rotating parts are isolated by protective cover to avoid accidents and higher safety factor.