Tel : 0086 21 5722 3896

E-mail : info@denair.net

Tel : 0086 21 5722 3896

E-mail : info@denair.net

Reciprocating Gas Compressor are widely used in many industries related to the compression and supply of gas to consumers. Like oil and chemical industry, oil refineries and more. Various technological processes can include corrosive, inert, poisonous and explosive gases, which must be treated to a clean gas without impurities of oil.

Depending on the type of equipment, work with different gases, such as:

Compressor units can be made on single frame design. With interstage devices and all necessary piping, placed on a single platform with a compressor.

Compressor units can be manufactured in the version "without lubrication of cylinders and oil seals"

The modern automation system of the compressor units guarantees the safety and easy use of the equipment.

Reducing the time of commissioning.

Application Field

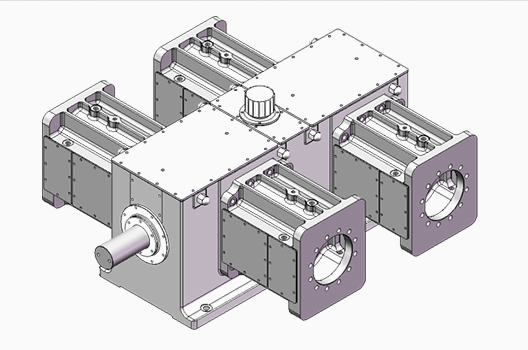

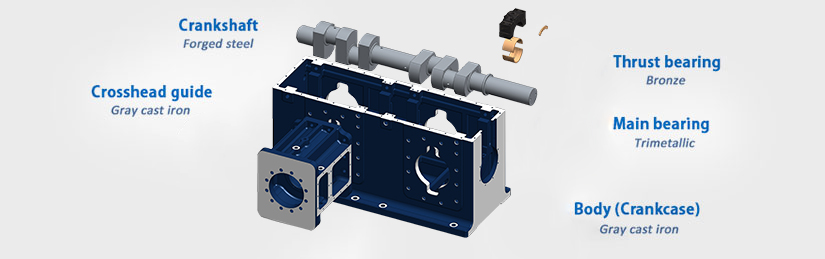

Rigid bed

DENAIR compressor frames are designed for long service life and ease of maintenance. Our antiques have a base made of ductile iron with massive stiffeners and a lightweight removable aluminum top cover.

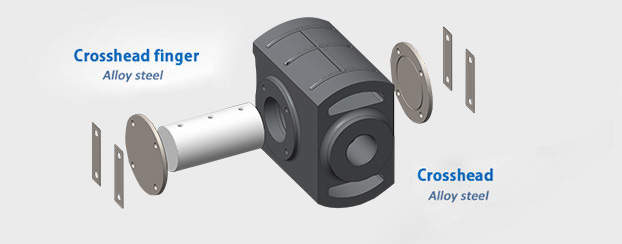

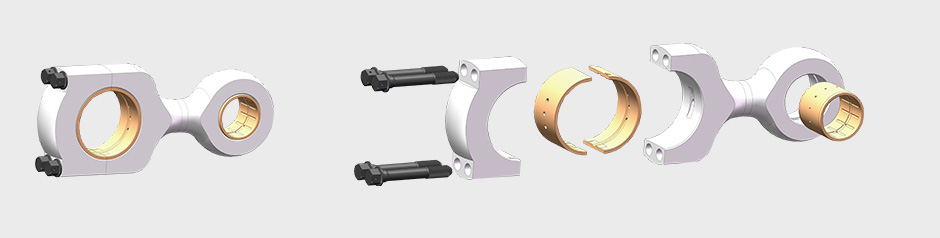

Durable crossheads

One-piece durable crossheads with ground hardened steel pins, pressure lubricated top and bottom sliding surfaces for maximum wear.

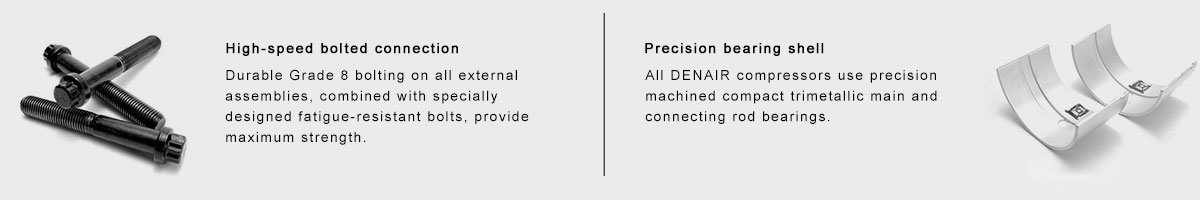

High strength connecting rods

The compressors are characterized by the use of durable ductile iron connecting rods with a four-bolt cover attached to the high-strength I-beam body.

Innovative cylinders

DENAIR's proven cylinder design eliminates the cost of a cylinder cooling system, eliminates complexities and eliminates the potential for maintenance problems. Associated with water cooling such as scale and corrosion.

DENAIR is committed to delivering integrated compression solutions tailored to our customers' specific requirements. We offer all series of compressors with electric motor or gas engine to ensure safe and reliable operation.

DENAIR's packaged units can be used both onshore and offshore with a range from 85 HP to 10,000 HP.

Extensive application experience from oil and gas fields to chemical plants gives DENAIR a deep understanding of customer needs as well as industry standards in different countries and regions. In addition, we can also provide engineering services for gas collection station, gas supply and underground gas storage facilities, etc.

Ambient temperature: -140 ℉ - 122 ℉ (-60 °C - +50 °C)

Pressure range: 0 - 8990 psi (0 - 61.98 MPa)

Power range: 10 HP - 10000 hp (7.46 - 7457 kW)

Process gas: natural gas, air, hydrogen, ethane, nitrogen, propane, CO2, BOG, etc.

Mounting types: automotive, stationary, mobile and pile mounting

Application: injection, collection, utilization of associated gas, injection of fuel gas, CNG, etc.

If you are interested in DENAIR air compressor, please contact us via

email: info@denair.net or send your inquiry in the form below.we will reply you within 24 hours.

*

*

*

Privacy Policy © 2006 Denair Energy Saving Technology (Shanghai) PLC.